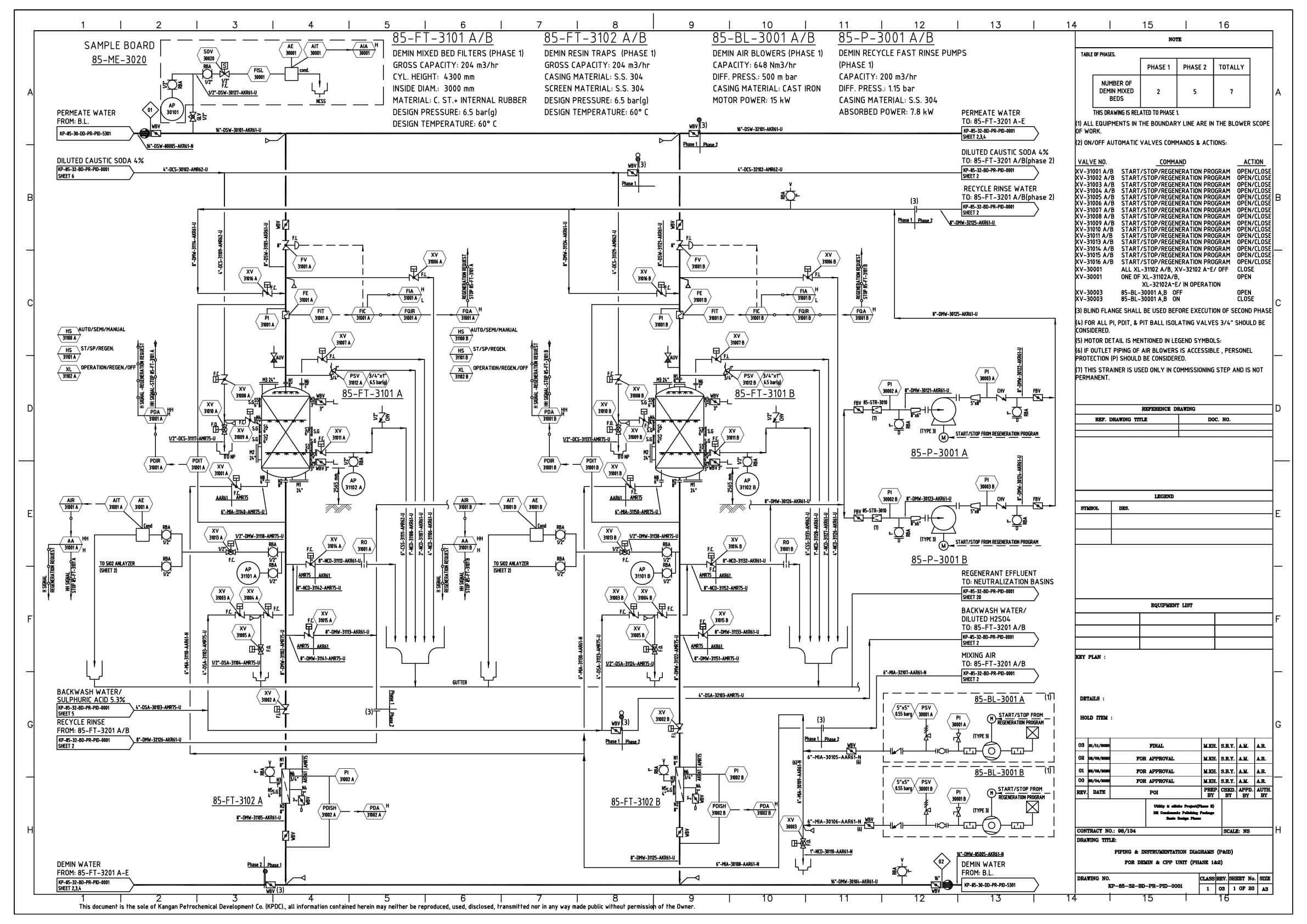

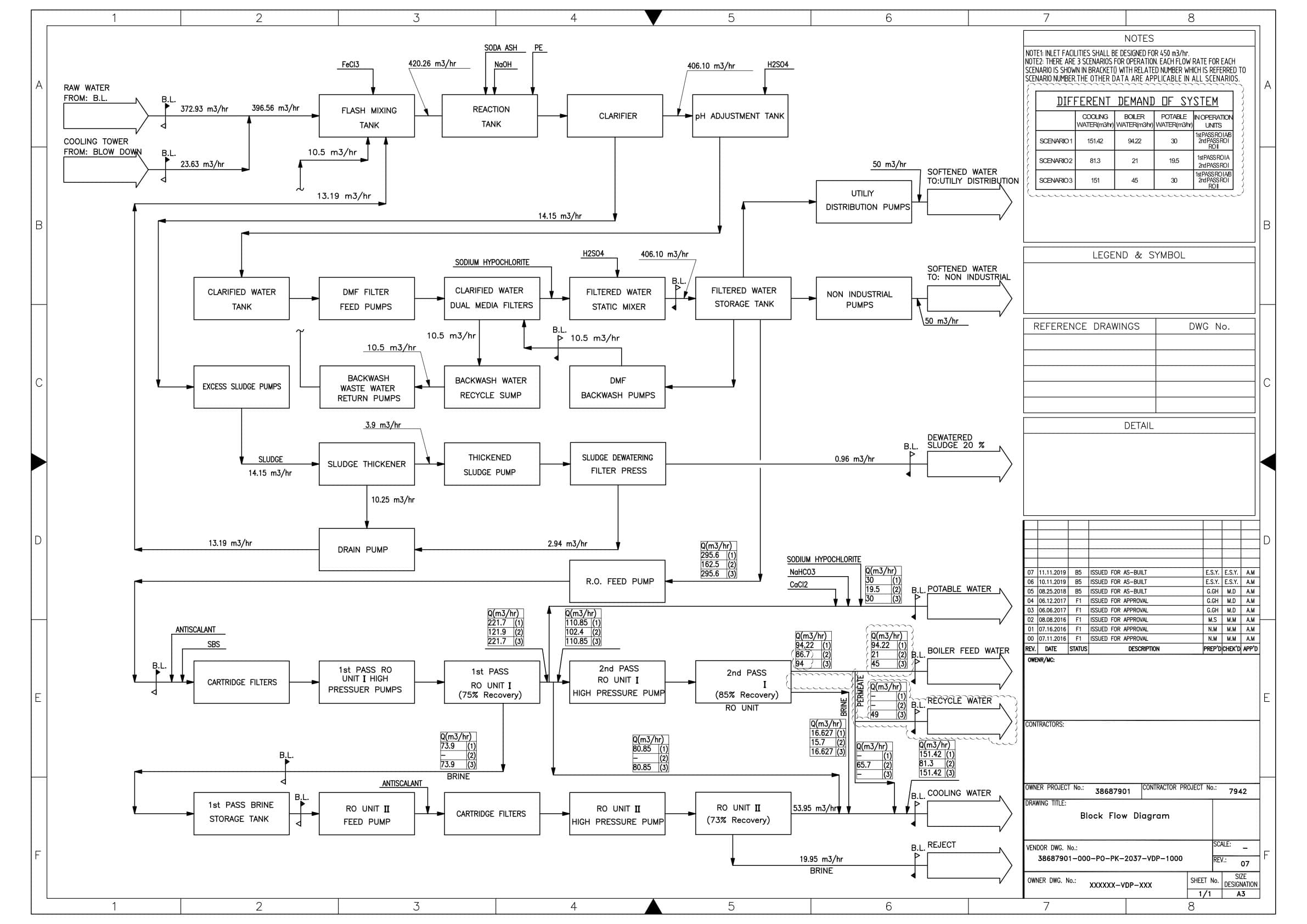

RWT engineering design teams can execute a full range of designs and specifications for all aspects of a water treatment plant. Our design teams provide multidisciplinary engineering design for new Greenfield sites to achieve a fully operational water treatment plant. We are able to perform basic engineering studies previous to detail design and execution phases with a multidisciplinary team of technicians and engineers. Basic engineering package typically includes the following deliverables: Design Basis: standards and codes for design, Site condition information as well as required characteristics of utility supply systems are summarized. Process Description: The purpose and characteristics of key process unit operations and equipment are outlined in narrative form. Equipment List: A list is provided to identify all required process equipment. Process Flow Diagrams and Heat & Material Balances: A process calculation for the plant is developed. All process streams are defined in tabular and flow sheet format. Temperatures, pressures, flow rates, and physical properties at normal operating conditions are defined for all process streams. Piping and Instrumentation Diagrams: A diagram is provided to show the interconnection of process equipment and the instrumentation used to control the process. Interconnection of key process utilities is also identified. Process Equipment Data Sheet: Process data sheets are provided for all Inside Battery Limit (ISBL) equipment items. Instrument List: Control valves, level instruments, flow instruments, pressure instruments, temperature instruments and relief devices are identified and provided. Piping: A piping specification and piping classification index are provided. Utilities Consumption: Required chemicals and utilities are identified and consumption rates are specified. Preliminary plot plan: A preliminary plot plan to specify all process equipment and basins as well as process and administration buildings are provided. ...

Read More

Detailed engineering is a very important process in any project that requires the application of knowledge into action. It is the last of three implementation phases in engineering where the process in the first two phases are described in great detail. In detailed engineering design, every sub process, and equipment relevant to the project is properly documented, procured and implemented. While the project viability is determined in basic engineering, every detail concerning the entirety of the project including end‐user satisfaction and functionality are covered in detailed design. RWT offers best‐in‐class multi‐disciplinary design and detail engineering support services in the areas of process, piping, mechanical, civil and structural, electrical, instrumentation and control disciplines. The following document and drawings are samples for detail design engineering which are provided by RWT: Complete plant layout services, including equipment arrangement, plot plan 2D and 3D equipment and piping modeling Static and dynamic piping stress analysis Design and selection of static and rotating equipment such as pumps, vessels, tanks and heat exchangers, columns and agitators Preparation of technical specifications for procurement of equipment Generation of fabrication drawings Technical bid evaluation Vendor co‐ordination and Expediting services Electrical load analysis and design of system architecture Power distribution system design Motor control center and sub‐station design Protective relay coordination Lighting design Grounding design Cable and tray routing, sizing, scheduling Hazardous area classification Supervisory Control and Data Acquisition (SCADA) design and specification Plant communication system design Complete Control System design and architecture Distributed Control System (DCS), Programmable Logic Controller (PLC) Control valve sizing and selection Instrument design and specification ...

Read More

There are different new technologies in treating water and wastewater for urban or industrial purposes. Technology selection represents a crucial decision in the early stages of a project which can have a substantial impact on the economic viability of the project. Hence the need for a disciplined technology evaluation methodology to ensure that the most appropriate, efficient and cost effective solution is selected. New technology can provide benefits and this should be weighed up against the increased risk resulting from inaccuracies in, or insufficient, design data and often prolonged start‐up duration. RWT process team study the new technologies in detail and with rich experience of various process design emphasize the balance between practical and theory. Our process team asses and compare different technologies for client to find the best competitive choice to meet client’s requirements as well as project sustainability, social acceptance and local environmental regulations. ...

Read More

Are you looking for to buy water treatment facilities with the lowest price? RWT can help you. The main objective of RWT’s supply strategy is to maximize the value of investments on behalf of the owner. Procurement is made according to a process that ensures safe delivery of goods and services at the right price, at the right time and at the right quality. Our procurement engineers utilize their multi‐ disciplinary backgrounds to provide the owner the right and the best equipment in water and wastewater field that bridge engineering, quality assurance, purchasing, technical, and manufacturing functions. We also engage directly with suppliers to understand their systems and processes. ...

Read More

Procurement engineering is required to be carefully managed to maintain the economic and financial viability of water and wastewater treatment facilities. Procurement engineering has a direct connection to plant costs. Wrong procurement results on failing the process or cause considerable operating cost. RWT’s procurement engineering division provides qualified engineers in all technical disciplines including process, mechanical and electrical to assess all technical points of the goods, equipment or packages and also optimize the supply chain, reduce exposure to supplier risk, achieve cost savings, and diversify supply sources. Procurement engineering encompasses: Assist in Finalization of Vendor List Preparation of Technical Procurement Package Technical Bid Analysis (TBA) Preparation of Purchase Specifications Review of Vendor Drawings and Documents Finalization of ITPs ...

Read More

How to approach the problem? Meet our water treatment experts. Our water treatment consultants can help you to find a solution that matches your requirements, conditions and budget. In the technology, engineering, and construction of water and wastewater treatments, RWT provides sustainable solutions to the clients, using our strong foundation in science to address regulatory requirements, state‐of‐the‐art technology, and examine economical options. RWT’s wastewater treatment specialists combine their expertise in the design and operation of biological and physical and chemical processes to meet our client’s needs for effective, efficient treatment facilities. Our engineers regularly perform hands‐on process energy audits, comprehensive performance evaluations, and plant optimization. Our dedicated team of design engineers offer expert support in creative problem solving, conceptual design, basic engineering, detail design, manufacturing drawings, technology advice and selection, and procurement engineering. ...

Read More

Conceptual design is the first or a very early phase of the design process. The conceptual design of a project involves the choosing of a certain solution among the many possible which must be studied in order to solve a particular problem. In the conceptual design phase designers explore ideas for the project using a variety of technology and process to achieve project goals and overcome project limitation including site plan, project budget, local regulation, level of automation and operating cost. The following documents are provided during the phase of the conceptual design: Process flow diagram for definition of the functionality, capacity and configuration of the system or plant. Basic 2D layout with optimized arrangement of process equipment and building Utility requirement list for dimensioning the energy supply systems Plant inlet and outlet specifications Production plan und capacity analysis Milestone schedule for the project ...

Read More